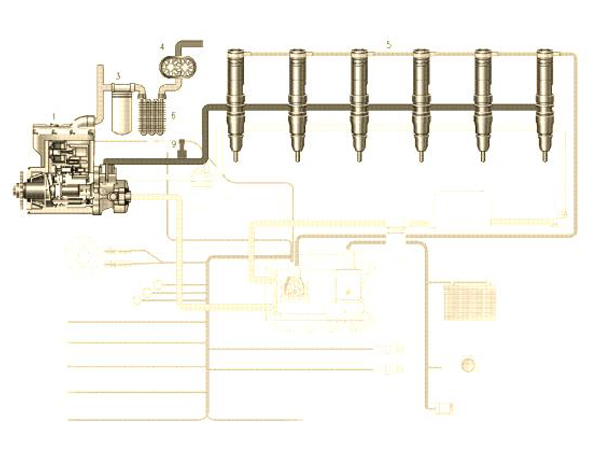

The HEUI injector system adopts medium pressure common rail injection technology, which increases the injection pressure by lifting the booster piston. There are two oil passages inside the engine: one is a medium pressure oil passage, which provides 10-28MPa pressure oil and drives the booster piston; The other is the low-pressure oil circuit, which is responsible for delivering injected fuel to the injectors. In addition, the electrical control part of the system has many similarities with the high-voltage common rail system.

1. System features

The HEUI system adopts medium pressure common rail electronic hydraulic injection technology, and the oil pressure in the common rail is maintained within the range of 40-230 Bar. The system optimizes injection performance by controlling the pressure regulating valve in the common rail through ECU. In addition, the system also has the following characteristics:

(1) The system uses diesel engine lubricating oil instead of fuel in the common rail, and has two sets of dedicated lubricating oil and fuel circuits to ensure the stability and durability of the system.

(2) The fuel boosting piston is driven by the oil pressure of the common rail oil passage, and high-pressure injection is achieved through a design with a ratio of the area of the large and small pistons of 7:1, with an injection pressure of up to 1600Bar.

(3) By precisely controlling the inflow and outflow of oil in the common rail oil passage through high-speed switch solenoid valves, rapid adjustment of fuel pressure can be achieved, thereby achieving precise control of injection timing.

(4) The system also has a pre injection channel, which achieves pre injection function by controlling the initial injection rate, further improving the performance of the engine.

(5) The injection pressure is independent of the speed and load of the diesel engine, ensuring stable injection performance under different operating conditions.

2. System advantages

The HEUI system is based on time in fuel metering, and its injection pressure remains stable, unaffected by engine speed and load. At the same time, the injection timing also has extremely high flexibility. By carefully designing the cross-sectional area ratio of the booster piston to the plunger, this system can easily achieve very high injection pressures. In addition, the HEUI system only generates high voltage when necessary, improving efficiency. It is worth mentioning that its solenoid valve is only used to control the medium pressure oil circuit, and the manufacturing difficulty is relatively low. At present, the HEUI system adopted by Caterpillar in the United States has been widely used in C7 and C9 engines, which are also quite common in the domestic market.

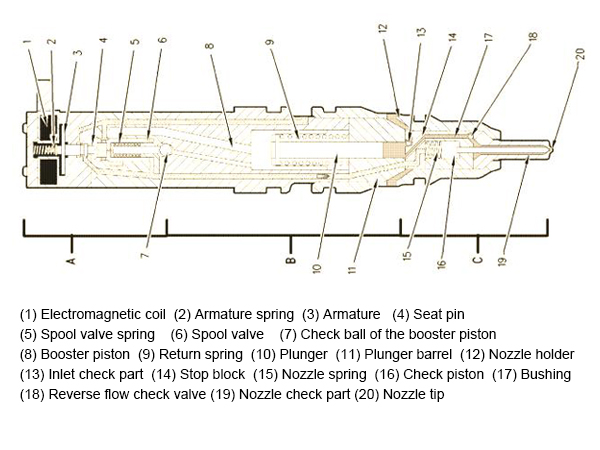

3. Structure and function of fuel injector

The HEUI injector integrates multiple functions. Firstly, it can pressurize the supplied fuel to a wide range of 450 kPa to 175 MPa. Secondly, the working principle of the fuel injector is similar to that of the spray, which accurately sprays high-pressure fuel through the orifice at the tip. In addition, HEUI injectors can ensure that an appropriate amount of atomized fuel is accurately injected into the combustion chamber and evenly dispersed.

The HEUI injector consists of three key components:

A. The upper end (actuator) includes components such as electromagnetic coil, armature, armature spring, slide valve, slide valve spring, seat pin, and boost piston check ball.

B. The middle part (pump oil device) includes components such as booster spring, return spring, plunger, and cylinder.

C. The lower end (nozzle component) consists of a nozzle shell, stopper, inlet check piece, liner, reverse flow check valve, nozzle spring, check piston, nozzle check piece, and nozzle tip.

These components work together to achieve precise fuel injection rate control. It is worth mentioning that the fuel injection rate itself is precisely controlled electronically through performance software within the ECM.

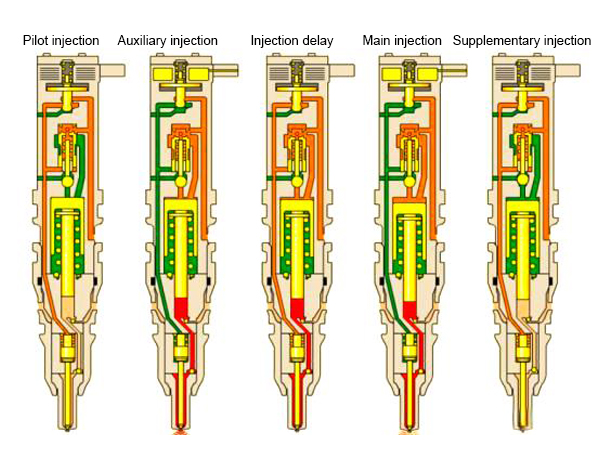

4. Working principle

The HEUI injector carefully divides the separated fuel injection cycle into five different injection stages during the fuel injection process to ensure precise fuel injection control. These stages include: pre injection, auxiliary injection, injection delay, main injection, and supplementary injection.

Overview of Maintenance and Measurement

When repairing HEUI injectors, we need to master a series of measurement methods. These methods not only help us determine the working status of the fuel injector, but also guide us in necessary maintenance operations. Through these measurements, we can ensure that the performance of the fuel injector reaches its optimal level, thereby guaranteeing the normal operation of the engine. The measurement methods for key components of HEUI fuel injectors include specific measurement steps for stroke and air clearance.

Detailed measurement steps

When repairing HEUI injectors, the first step is to measure the stroke of the oil control valve. For this, we need to prepare a tool for measuring the stroke of the oil control valve and install a dial gauge as required to ensure its stability. Next, we can proceed with the relevant measurement operations. The use of specific measuring tools emphasizes the accuracy of measurement.

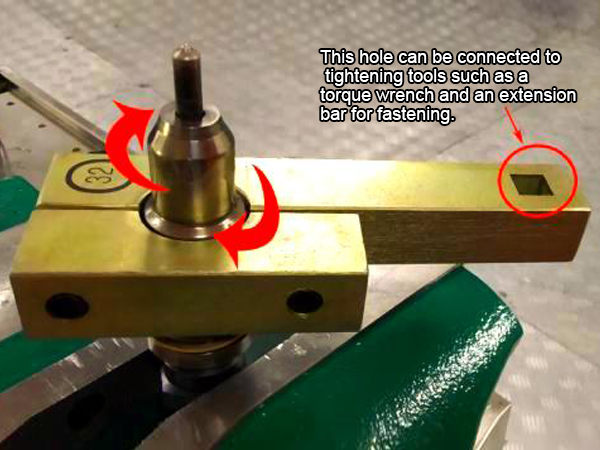

(1) Carefully place the oil control valve into the corresponding position of the travel measuring tool and ensure that the travel measuring tool is tightened to ensure measurement accuracy.

(2) Press the in/mm key to switch the measurement unit of the dial gauge to the millimeter (mm) scale; Subsequently, press the ZERO button on the dial gauge to perform the zeroing operation.

(3) Insert the top rod into the reserved hole at the bottom of the oil control valve stroke measuring tool and lift it up. After the data display stabilizes, the stroke value can be read.

In addition, there are measurement methods for the air clearance stroke of the oil control valve and the needle valve stroke of the oil needle, which require detailed steps for accurate measurement.

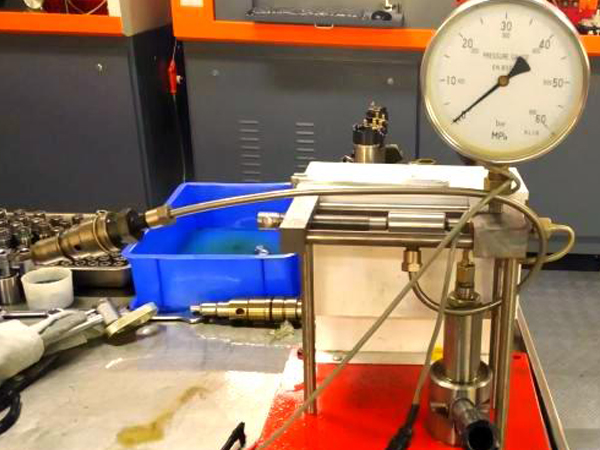

Start spray pressure test

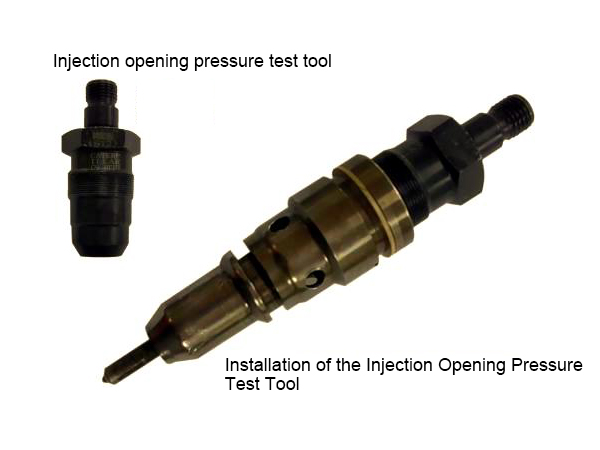

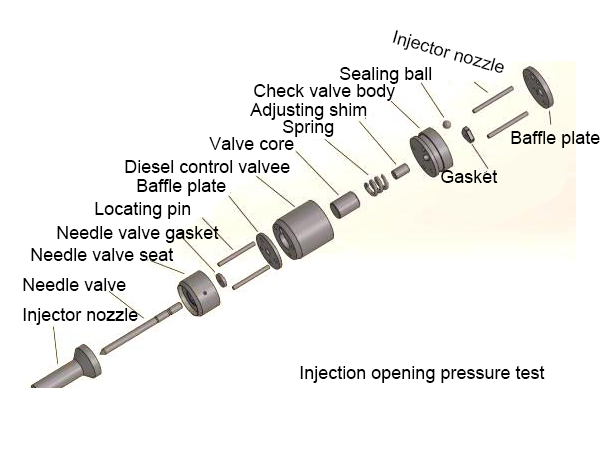

The injection pressure test requires the use of injection pressure testing tools and the observation of the atomization state of the fuel injector to determine its performance. By observing the atomization condition of the fuel injector, determine whether it is normal.

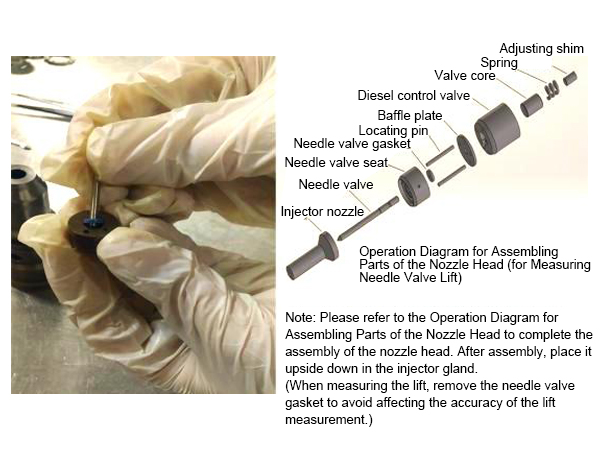

Firstly, it is necessary to remove the injection pressure testing tool and assemble the diesel components of the fuel injector correctly according to the relevant guidelines.

After loosening the pliers, remove the spray pressure testing tool and then install it on the calibrator, ensuring that the fuel supply screw is tightened.

Continuously press down on the pressure rod and gradually increase the pressure to 22MPa, at which point the fuel injector should start spraying.

Maintenance Process

Fault diagnosis through various test reports is an important step in HEUI injector maintenance. Covering multiple possible fault locations and conducting fault diagnosis through data analysis methods.

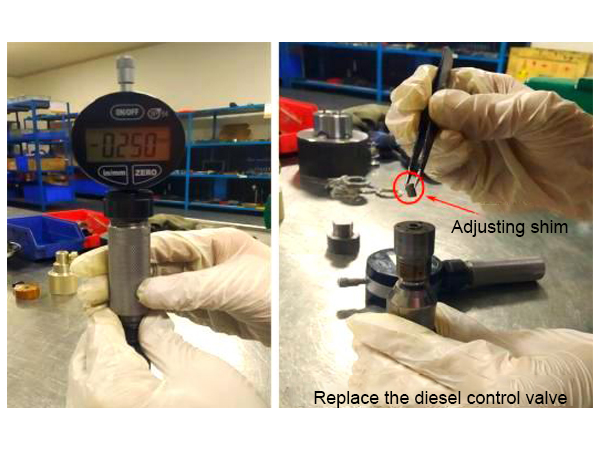

After disassembling the fuel injector, it is necessary to measure the stroke of the oil control valve, the air clearance stroke of the oil control valve, and the stroke of the needle valve in sequence. Based on these measurement results, we can make preliminary fault diagnosis. The maintenance judgment methods provided below are for reference only, and the specific situation needs to be determined according to the actual situation.

If the test report of the test bench shows that the diesel fuel injection quantity is too large, there may be the following faulty parts: ① Diesel valve; ② Oil control valve; ③ Fuel injector; ④ Oil needle seat, oil needle. If the test report shows that the diesel fuel injection quantity is too small, the possible problems are: ① intermediate pressure plate; ② Oil control valve; ③ Air gap pad; ④ Fuel injector.